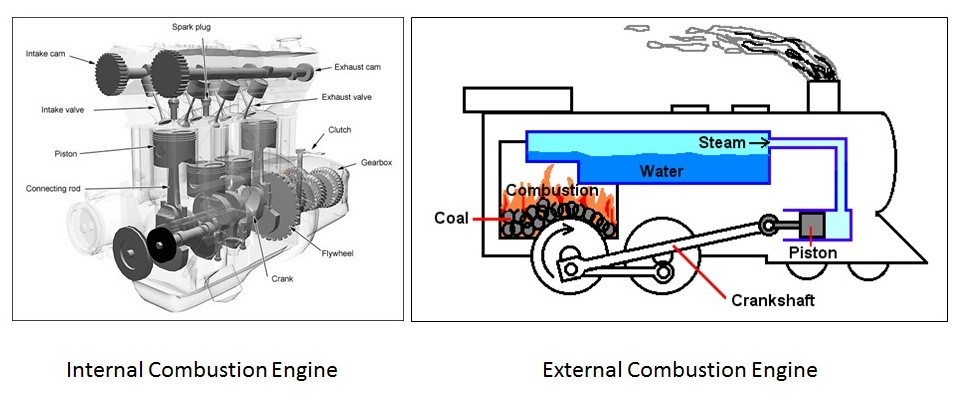

These days, all cars and light trucks use four-stroke piston engines, whether burning gasoline or diesel. This means that the crankshaft must go around twice, and each piston moves up and down two times, to produce one pulse of power. To put it another way, the piston goes up-down, up-down, for each firing of the spark plug.

With a four stroke engine, all the cylinders fire within two turns of the crankshaft. On an eight cylinder engine, the coil discharges every 90 degrees or 1/4 turn of the crankshaft. A four cylinder engine would fire every 180 degrees or 1/2 turn. This limits the amount of time the coil can build up especially at higher RPM’s. Type: LOVSON Diesel Engine is SINGLE CYLINDER, vertical, totally enclosed compression ignition, four stroke cycle, cold starting diesel engine tested as per IS. For a typical passenger vehicle engine, the maximum cylinder pressure can be around 120 bar (gasoline) or 180 bar (diesel). The power stroke starts when the piston moves from TDC towards BDC. The high pressure in the cylinder is pushing the piston, therefore the volume rises and the pressure starts to drop gradually. Are there any successful project out there, chaining two 4 stroke single cylinder? Depends on your definition of success but it can be made to work. Will the engine sounds be good? I mean, because of the chain's tension, will the shaft sync as good as welding the shaft? This depends on supporting mods like the exhaust design.

Two stroke engines these days are only found in chainsaws, weed whackers, snowmobiles, outboard boat motors, and mopeds. These type of motors may make more power for a given size or weight, but they produce much more pollution.

The Wankel Rotary engine, as most recently used by Mazda in the RX-7, works on a different system entirely. I could be thought of as a three stroke engine, but in reality it doesn't have any strokes at all.

In a four-stroke engine, the four strokes are:

1) Intake Stroke

Starting from 'Top Dead Center' (TDC), and zero degrees of rotation, the piston moves down the cylinder. As the piston moves it creates a vacuum and the intake valve opens, sucking air into the cylinder. On carburetted engines, and on port and throttle body injected motors, the fuel come in with the air, while on direct injected motors it is squirted directly into the cylinder.

2) Compression Stroke

Now at 'Bottom Dead Center' (BDC), the piston starts to move up again. The intake and exhaust valves are both closed and the fuel and air mixture is compressed by the piston into the combustion chamber. These days the compression ratio, the volume of the cylinder plus combustion chamber, compared to the volume of just the combustion chamber, can be anywhere from 8:1 to 12:1, or more in some race engines. Compressing the mixture greatly increases the amount of power produced by combustion, but the compression itself produced heat, which can cause detonation or pre-ignition.

3) Power Stroke

This is where all the magic happens! The spark plug fires igniting the mixture, as the piston is at the top of the stroke. The resultant explosion moves the piston rapidly back down the cylinder, turning the crankshaft,a nd making the car go. In a diesel engine, there is no spark, the mixture just spontaneously ignites at the right moment due to the heat of compression. In a single cylinder engine, at idle, you can practically hear each individual explosion.

4) Exhaust Stroke

The piston moves back up the cylinder because of the momentum produced during the power stroke and the weight of the flywheel (in a single cylinder motor), or due to the firing of other cylinders. The exhaust valve opens, and instead of compressing the burned gases, they are pushed out into the exhaust port. As the piston gets close to TDC again, the exhaust valve starts to close, and the intake starts to open, for a small period called 'overlap' where the escaping exhaust creates suction that helps pull air in via the intake valve opening. The cycle then starts again, with the piston moving down on another intake stroke.

Four Stroke Gas Engine

The four stroke gas engine is classically constructed with a bottom-mounted camshaft powered by gearwheels which operate valves via a ram, push rod and rocker arm.

A large flywheel with a flange-mounted ripcord-wheel facilitates comfortable and secure starting.

-lab-1439830316.jpg)

Single Stroke Engine

The gasification, i.e. the blending of gas and air, is achieved via a user-controlled carburettor. The desired rotation speed is adjusted via a lever.

Four Stroke Single Cylinder Engine The Mechanical

This reduced emission engine with a piezo high voltage ignition is very quiet and even at high rotation speeds produces a pleasant sound.

The engine consumes fuel economically and thanks to the open construction design displays a very satisfactory sequence of piston, crosshead, push rods and rocker arms in motion.

| Would you like to buy the engine? Place your order by e-mail: info@maier-mechanic.com | |

| assembly instructions and technical drawings (PDF) | |

| the price includes the VAT | |

| kit | out of stock |

|---|---|

| ready to use complete engine | € 660 |

| model | four stroke gas engine MM-4 |

|---|---|

| rotation speed control | via carburettor |

| crank shaft | 3-fold ball bearing mounted |

| cylinder capacity | 1.5 cm³ |

| rotation speed | 200–2,500 rpm |

| ignition | piezo high voltage ignition |

| running time | 40 min/tankful (idling mixture) |

| height × width × length | 220 mm × 120 mm × 180 mm |

| weight | 2,300 g |